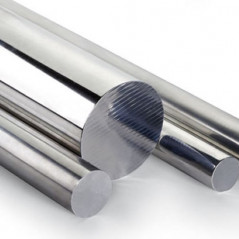

Alloy 625 Rod Inconel® From 12 To 220mm Round Rod 2.4856 UNS N06625

Properties of material 2.4856: high resistance to pitting, crevice and erosion corrosion; good resistance to alkalis and organic acids; high strength; good heat resistance;

Main applications for material 2.4856: chemical industry; marine and environmental technology; oil and gas industry; aircraft construction, shipbuilding; nuclear industry;

Length tolerance +/-3mm

Description:

- Production time - 5-7 weeks.

- Preparation for dispatch - 2-3 working days.

- Delivery time - depending on the parcel service. Please look at the faq.

If you need rods made of the material 2.4856, buy them from the online shop Auremo at favourable prices.

The material 2.4856 is characterised by excellent resistance to pitting, crevice corrosion, erosion and intergranular corrosion. The rods made of 2.4856 are highly resistant to mineral acids and alkalis and organic acids such as nitric, phosphoric, sulphuric and hydrochloric acid and have excellent mechanical properties.

The round rods made of 2.4856 / Alloy 625 are used in the oil and gas industry, chemical industry, marine engineering and environmental technology.

Rods made from 2.4856 are used as a suitable filler material for corrosion-resistant coatings on less resistant steels.

Properties of the material 2.4856:

- High resistance to pitting, crevice and erosion corrosion

- Good resistance to alkalis and organic acids

- high strength

- good heat resistance

Main application of the material 2.4856:

- Chemical industry

- Marine and environmental technology

- Oil and gas industry

- Aircraft and shipbuilding

- Nuclear industry

In our online shop Auremo you will find various sizes of nickel rods, we also have a large selection of other rods at favourable prices. If you have any questions, please contact us.

Technical data

| Brand: | Auremo |

| Country and region of manufacture: | Germany |

| Manufacturer number: | Not applicable |

| Type: | Rod, Rubbing bar |

| Standard classifications: | |

| Material number: | 2.4856 |

| EN: | NiCr22Mo9Nb |

| UNS: | N06625 |

| Alloy: | 625 |

Chemical composition (in %):

| Ni | Cr | Cu | Al | Mn | Nb | Si | Mo | Fe |

| max. 58% | 20.0-23.0% | 0.5% | 0.4% | 0.5% | 4.15% | 0.5% | 10.0% | 5.0% |

Mechanical properties (standard values at 20°C):

| Tensile strength Rm N / mm² | 0.2% Yield strength Rp - N/mm2 | Elongation A5 % | Hardness HB 30 | Scale resistance °C |

| 850-1050 | 415 | 30 | 240 | 1000 |

Physical properties (approximate values at 20°C):

| Density g/cm3 | Specific heat J/kg K | Thermal conductivity W/(mK) | Electrical resistance Ω-mm2/m |

| 8.5 | 410 | 10 | 1.29 |