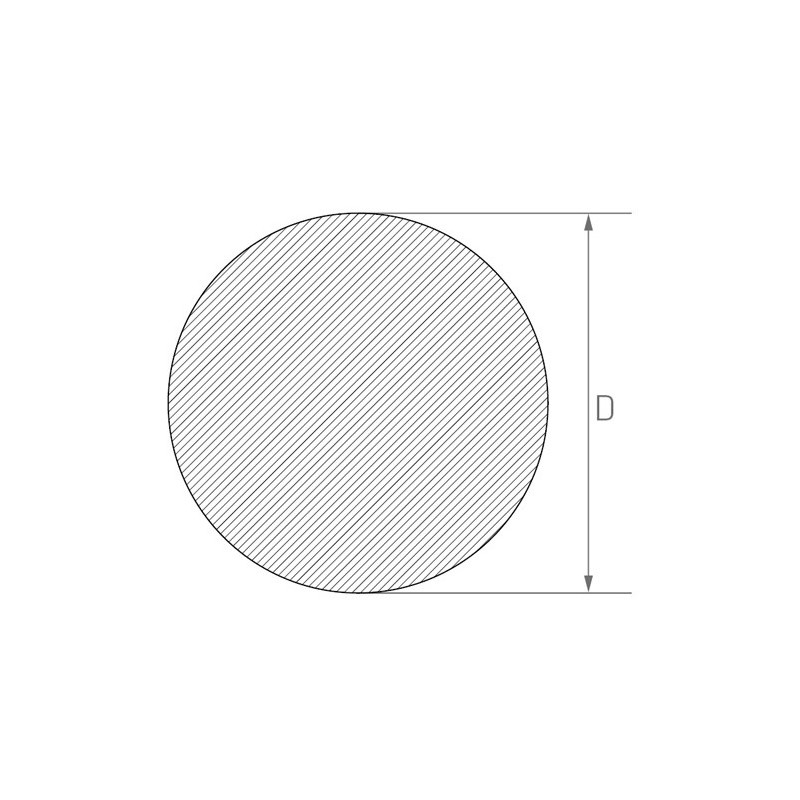

Alloy 75 Rod Nimonic® From 12.7 To 101.6mm Round Rod 2.4951 UNS N06075

Properties of material 2.4951: excellent resistance in oxidising environments up to 1000 °C; good mechanical properties at high temperatures;

Main applications for material 2.4951: steam and gas turbines; nuclear technology; furnace construction; heat treatment plants; environmental technology;

Length tolerance +/-2mm

Description:

- Production time - 5-7 weeks.

- Preparation for dispatch - 2-3 working days.

- Delivery time - depending on the parcel service. Please look at the faq.

If you need rods made of the material 2.4951, buy them from the online shop Auremo at favourable prices.

The material 2.4951 is an 80/20 nickel-chromium alloy with controlled additions of titanium and carbon. This product was first introduced in the 1940s for turbine blades in the Whittle jet engine prototype and is mainly used for sheet applications requiring medium strength due to oxidation and scaling resistance at high operating temperatures. W.Nr. 2.4951 is currently used in gas turbine technology as well as for industrial heat treatment, furnace components and heat treatment equipment. It is easy to manufacture and weld.

The material 2.4951 should be annealed before welding, but a small amount of cold forming is tolerable. The allowable amount of cold working varies depending on component design, but simple bending and rolling does not necessarily involve pre-annealing prior to welding. The heat affected zone produced by 2.4951 material does not cause weld seam decay and post-weld heat treatment is not normally required. If the equipment is required to operate in contact with caustic soda, fluorosilicates or some mercury salts, a stress relieving treatment may be desirable.

Properties of the material 2.4951:

- excellent resistance in oxidising environments up to 1000 °C

- Good mechanical properties at high temperatures

- good corrosion resistance

Main application of the material 2.4951:

- Steam and gas turbines

- nuclear technology

- furnace construction

- Heat treatment plants

- environmental technology

In our online shop Auremo you will find various sizes of nickel rods, we also have a large selection of other rods at favourable prices. If you have any questions, please contact us.

Technical data

| Brand: | Auremo |

| Country and region of manufacture: | Germany |

| Manufacturer number: | Not applicable |

| Type: | Rod, round rod |

| Standard classifications: | |

| Material number: | 2.4951 |

| Alloy: | 75 |

| UNS: | N06075 |

| EN: | NiCr20Ti |

Chemical composition (in %):

| Fe | Ni | Cr | Si | Co | Ti |

| max. 5.0% | Rest | 21.0% | 1.0% | 5.0% | 0.6% |

Mechanical properties (standard values at 20°C):

| 0.2% Yield strength Rp - N/mm2 | Tensile strength MPa | Elongation at break A5 % | Modulus of elasticity kN / mm² |

| 235 | 640 | 26 | 221 |

Physical properties (standard values at 20°C):

| Density g/cm3 | Specific heat J/kg K | Thermal conductivity W/(mK) | Electrical resistance Ω-mm2/m |

| 8.2 | 420 | 13 | 1.03 |