Welding wire Hastelloy® C22 TIG 2.4602 Nickel Welding rods Alloy 22 NiCr21Mo14W

Welding wire Hastelloy® C22 TIG 2.4602 Nickel welding rods Alloy 22 NiCr21Mo14W

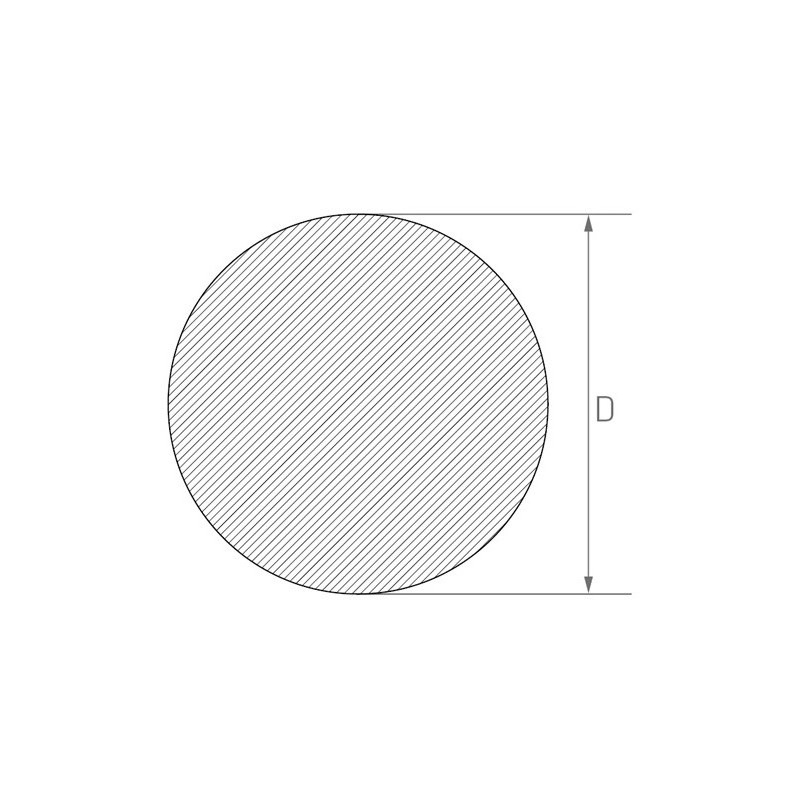

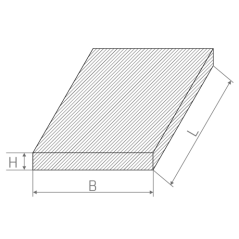

Length tolerance can be up to +/-2%

Description:

The uniqueness and versatility of the alloy Inconel® C22, Hastelloyl® C22 is manifested in the fact that due to its composition - nickel-chromium-molybdenum-tungsten, it has high resistance to various corrosive formations such as crevice corrosion, local selective corrosion and is not susceptible for stress corrosion cracking at high temperatures.

The high percentage of chromium in the composition is responsible for good resistance in oxidizing environments. Molybdenum and tungsten provide resistance to localized corrosion.

Alloy 22 is characterized not only by resistance to oxidizing aqueous media, but also has high resistance to chloric and nitric acid solutions and all acidic media with chlorine ion inclusions.

Hastelloyl® C22 can be cold and warm formed. The hot forming temperature is between 950 and 1230 °C. All the usual forming processes can be used. The material tends to work harden. After hot and cold forming with degrees of deformation > 15%, solution annealing is recommended to ensure optimum corrosion resistance.

Properties of Inconel® C22:

- excellent corrosion resistance;

- high resistance in oxidizing and reducing media;

- good weldability;

- good resistance to crevice, pitting and stress corrosion cracking;

Main application of the material 2.4602:

- Pharmaceutical Industry;

- equipment for chlorination plants;

- Manufacture of pesticides;

- chemical industry;

- waste water treatment.

A large assortment of various metals from the Auremo company are supplied wholesale or retail at the best prices. If you have any questions, contact us.

Technical specifications:

| Brand: | auremo |

| Manufacturing Country And Region: | Germany |

| Manufacturer number: | Not applicable |

| Type: | welding electrodes |

| Material: | Nikel |

Chemical composition (in %):

| Mon | Cr | no | co | feet | W | Mn | S | V |

| max. 12.5 - 14.5% | 20.0 – 22.5% | rest | 2.5% | 2.0 – 6.0% | 2.5-3.5% | 0.5% | 0.015% | 0.35% |

Mechanical properties (room temperature):

| Tensile strength Rm N / mm² | 0.2% yield strength Rp - N/mm2 | elongation A5% | Hardness HB 30 | Modulus of elasticity N/mm2 |

| 690 - 950 | 310 | 45 | 240 | 205 |

Mechanical properties (room temperature):

| Tensile strength Rm N / mm² | 0.2% yield strength Rp - N/mm2 | elongation A5% | Hardness HB 30 | Modulus of elasticity N/mm2 |

| 690 - 950 | 310 | 45 | 240 | 205 |

Physical properties (room temperature):

| Density in g/cm3 | Specific heat J/kg | Thermal conductivity W/(mK) | Electrical resistance Ω mm2/m |

| 8.7 | 406 | 10.1 | 1.14 |

Data sheet

- Type

- Welding electrodes

- material

- Nickel alloy

- Material number

- 2.4602

- Alloy

- 22nd

Specific References