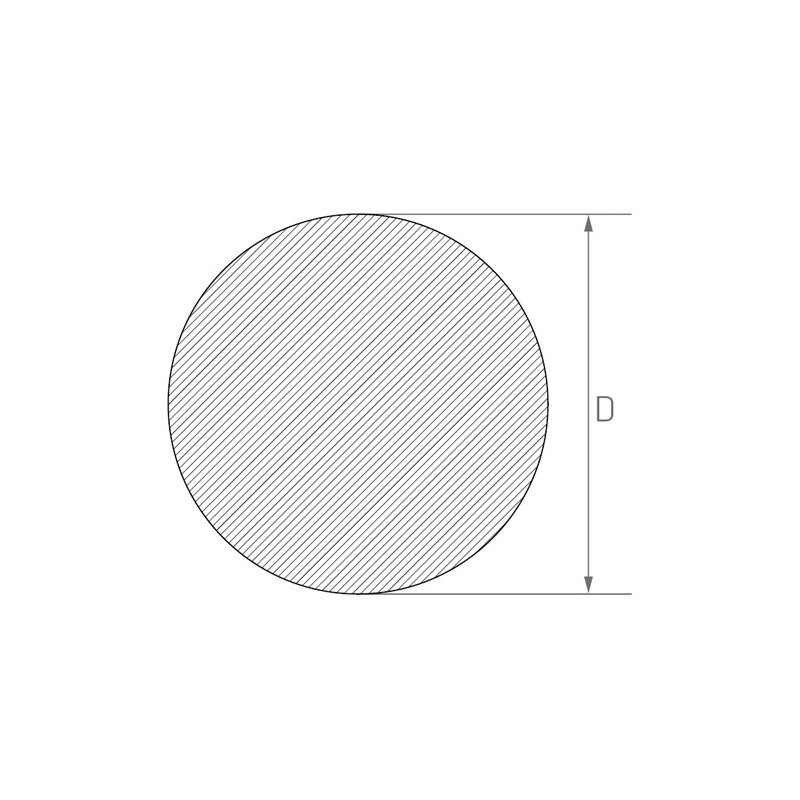

Welding wire NiCr-3 TIG 2.4806 Nickel Welding rods Nicrofer® S 7020 Ø 0.8-5mm

Welding wire NiCr-3 TIG 2.4806 Nickel Welding rods Nicrofer® S 7020 Ø 1.2-3.2mm

Length tolerance can be up to +/-2%

Description:

Material 2.4806 is used for welding and coating nickel-chromium-iron alloys such as Alloy 600, Alloy 601, Alloy 75 and the like.

Ni welding wire is used for heat-resistant, low-temperature-resistant and also corrosion-resistant connections in chemical apparatus construction and boiler construction. The weld metal is scale-resistant up to 1000° C and tough at sub-zero temperatures down to -269° C. The material 2.4806 is suitable for austenite-ferrite connections up to 550° C.

The wire has a stable chemical composition and belongs to the high-precision alloys with high electrical resistance. We recommend processing under protective gas argon 4.6 or higher.

Properties of the material 2.4806:

- high corrosion resistance;

- excellent heat resistance;

- tough at sub-zero temperatures down to -269° C;

- good weldability.

Main application of the material 2.4806:

- aircraft industry;

- Mechanical engineering;

- chemical industry.

Online shop Auremo offers only high-quality alloys at reasonable prices. If you have any questions, our customer service will be happy to help you.

Technical specifications:

| Brand: | auremo |

| Manufacturing Country And Region: | Germany |

| Manufacturer number: | Not applicable |

| Type: | welding electrodes |

| Material: | Nikel |

Chemical composition (in %):

| C | si | Mn | Cr | no | Nb | feet |

| max 0.02% | 0.1% | 3.0% | 20.0% | 67.0% | 2.5% | 2.0% |

Mechanical properties (room temperature):

| Tensile strength Rm N / mm² | 0.2% yield strength Rp - N/mm2 | elongation A5% | Impact work ISO – VJ At Rt |

| 620 | 380 | 35 | 90 |

Data sheet

- Type

- Welding electrodes

- material

- Nickel alloy

- Material number

- 2.4806

- US

- N06082

- Alloy

- 82

Specific References

You might also like

Uitstekende koper Snelle betal...

Uitstekende koper Snelle betaling Waardevolle klant A+++++

Report abuse