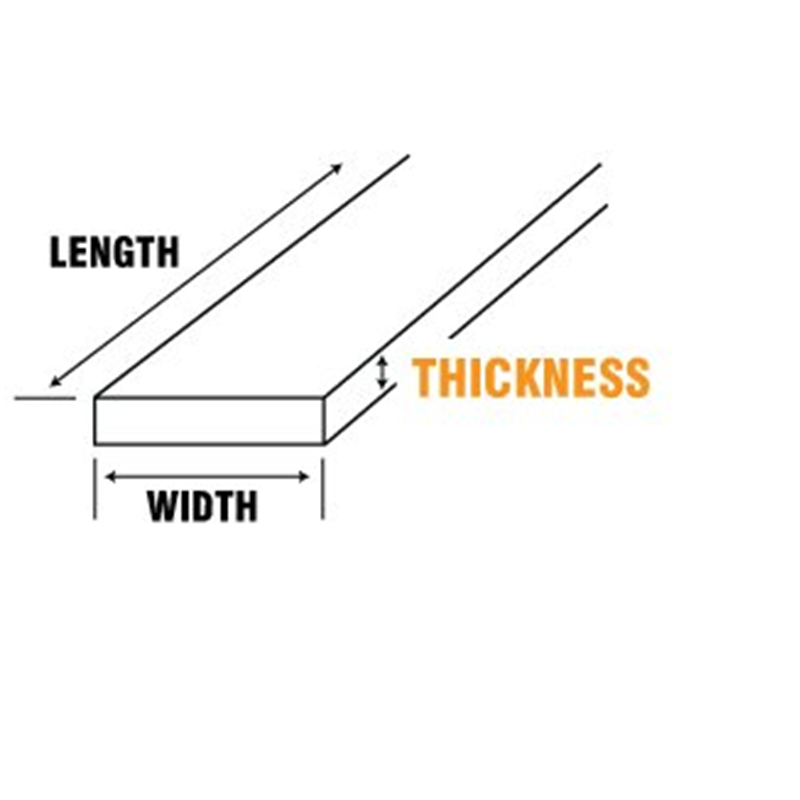

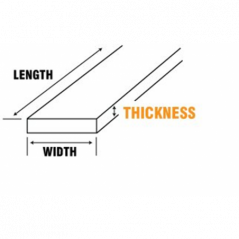

From 0.254mm to 25.4mm Alloy 625 sheet 2.4856 Inconel® plate Cut to size 100-1000mm

Properties of the material 2.4856: high resistance to pitting, crevice and erosion corrosion; good resistance to alkalis and organic acids; high strength; good heat resistance;

Main application of the material 2.4856: chemical industry; marine and environmental engineering; oil and gas industry; aircraft, shipbuilding; nuclear industry;

Length tolerance +/-3mm

Description:

- Production time - 5-7 weeks.

- Preparation for shipment - 2-3 working days.

- Delivery time - depending on the parcel service. Look at the FAQ please.

Inconel® 625 belongs to the group of nickel-chromium alloys with the addition of niobium and molybdenum. Such a complex structural composition contributes to a significant increase in the strength of the alloy without the need for thermal hardening.

Alloy 625 sheets can be operated under a wide range of temperature conditions, from minus to 980 °C. In addition, Inconel® Alloy 625 has a unique resistance to corrosion, especially when in direct contact with acids. It is characterized by high resistance to gas corrosion damage at high temperatures. The alloy is easy to weld either type.

Due to its composition, Inconel® 625 is in demand and indispensable in modern production of the oil and gas industry, chemical industry, aircraft construction, shipbuilding, instrumentation and in the manufacture of reactor parts in the nuclear industry.

Properties of the material 2.4856:

- high resistance to pitting, crevice and erosion corrosion

- good resistance to alkalis and organic acids

- high strength

- good heat resistance

Main application of Inconel® 2.4856:

- chemical industry

- marine and environmental engineering

- oil and gas industry

- aircraft, shipbuilding

- nuclear industry

Our online shop is pleased to offer you a large selection at a reasonable price. You can find out about the exact availability when purchasing from customer service.

Technical specifications:

| Brand: | auremo |

| Manufacturing Country And Region: | Germany |

| Manufacturer number: | Not applicable |

| Type: | Rod, Rubstabe |

| Norm classifications: | |

| Material number: | 2.4856 |

| EN: | NiCr22Mo9Nb |

| US: | N06625 |

| Alloy: | 625 |

Chemical composition (in %):

| no | Cr | Cu | Al | Mn | Nb | si | Mon | feet |

| max. 58.0 – 63.0% | 20.0 – 23.0% | 0.5% | 0.4% | 0.5% | 4.15% | 0.5% | 10.0% | 5.0% |

Mechanical properties (reference values at 20°C):

| Tensile strength Rm N / mm² | 0.2% yield strength Rp - N/mm2 | elongation A5 % | Hardness HB 30 | Scale resistance °C |

| 850-1050 | 415 | 30 | 240 | 1000 |

Physical properties (approximate values at 20°C):

| Density g/cm3 | Specific heat J/kg K | Thermal conductivity W/(mK) | Electrical resistance Ω mm2/m |

| 8.5 | 410 | 10 | 1.29 |