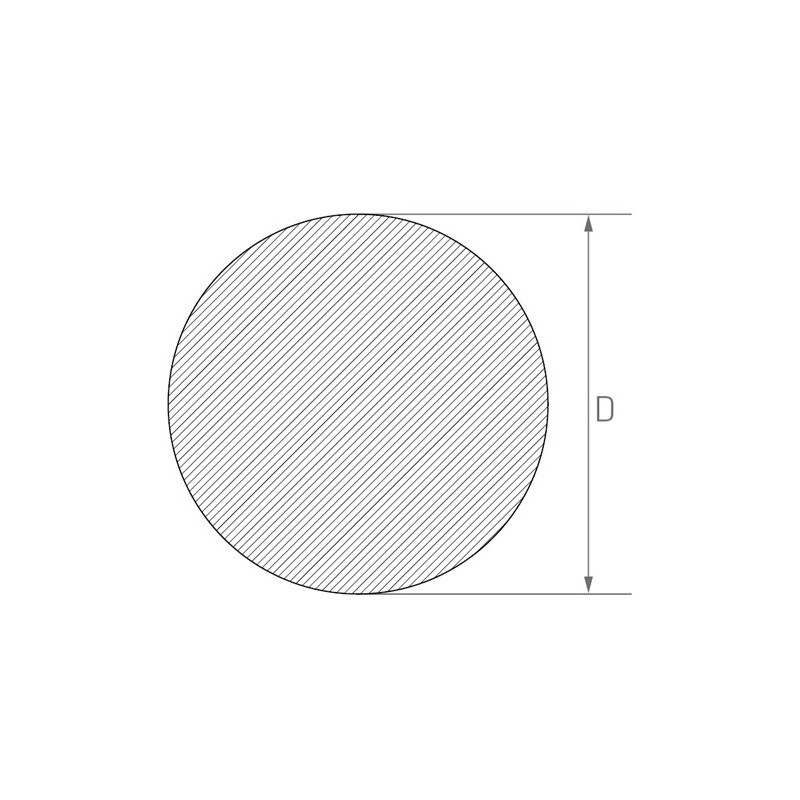

Brass Ms58 rod Ø0.4-400mm solid material 2.0401 round material

- Brass ms58 rod Ø1.5-60mm full material 2.0401 round material

Length tolerance +/-2mm

Description:

High quality brass is always available at a good price in the Auremo online shop. Brass is an alloy of copper and zinc combined with other metals.

A brass round bar made of the material 2.0401 is suitable for almost all types of processing, including welding and soldering. The material 2.0401 is characterised by corrosion resistance, good ductility, long service life and wear resistance.

The brass alloy is stronger than copper and more resistant to destruction by environmental influences. At low temperatures, the metal does not lose its ductility and remains resistant to fracture. At high temperatures, creep (slow deformation over time) is less than with copper. This property is due to the stronger recrystallisation. However, the electrical and thermal conductivity of brass is lower than that of copper.

The melting point depends on the zinc content: As the zinc content increases, the melting point decreases. On average, it is 880 - 940 °C. Outdoors, the surface of brass oxidises and darkens, which is why it is often coated with a special protective lacquer.

Brass rods have a relatively wide range of applications due to their properties.

Properties of the material 2.0401:

- excellent machinability

- good hot working properties

- good ductility

- wear resistance

Main applications for the material 2.0401:

- Screws

- Mechanical engineering

- Chemical industry

- Apparatus engineering

In our online shop Auremo you will find different dimensions of brass round rods, also we have a large selection of stainless steel rods at good prices. If you have any questions, our customer service will be happy to help you.

Technical data:

| Brand: | Auremo |

| Country and region of manufacture: | Germany |

| Manufacturer number: | Not applicable |

| Type: | Round bar |

| Standard classifications: | |

| Material number: | 2.0401 |

| EN: | CuZn39Pb3 |

| Alloy: | CW614N |

| DIN: | Ms58 |

Chemical composition (in %):

| C | Zn | Pb | Ni | Fe | Sn | Al | Other elements |

| max. 57 - 59 | Rest | 2.5 - 3.5% | 0.3% | 0.5% | 0.3% | 0.05% | 0.2% |

Mechanical properties (guide values at 20°C):

| Hardness HB 30 | 0.2% Yield strength Rp - N/mm2 | Tensile strength Rm | Elongation A5 % |

| 140 | 460 | 540 | 12 |

Physical properties (guide values at 20°C):

| Density g/cm3 | Solidification range °C | Thermal conductivity W/(mK) | Electr. conductivity MS/m |

| 8.46 | 880 - 895 | 113 | 0.068 |