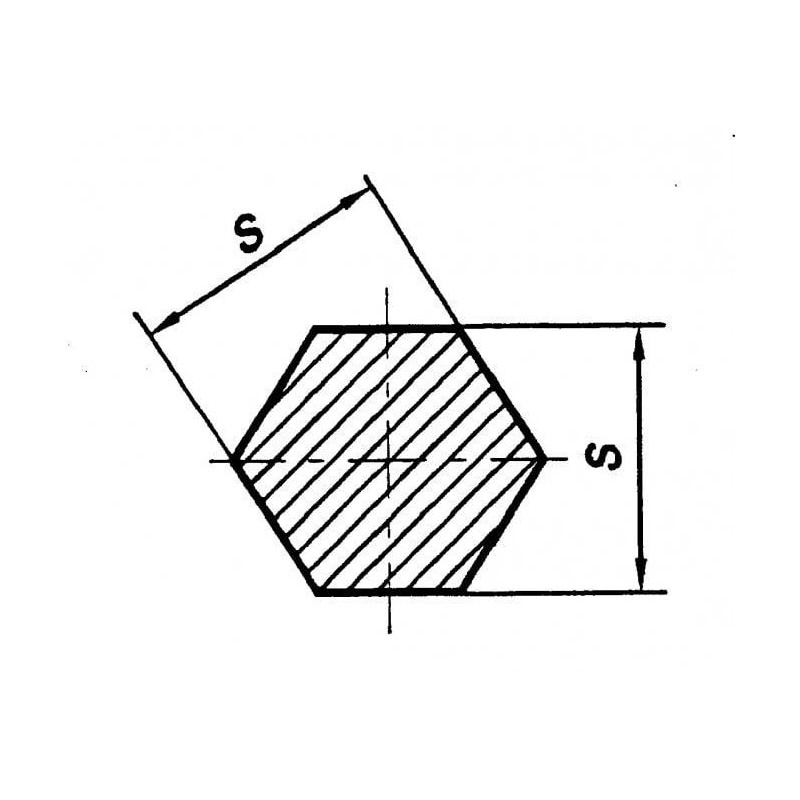

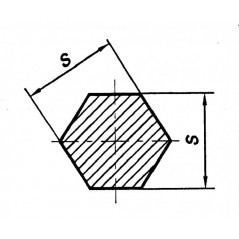

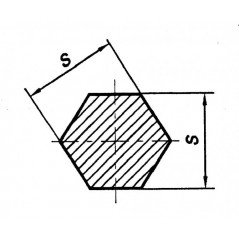

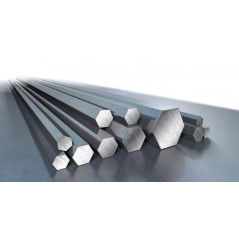

Brass hexagon 2.0401 SW 4mm-40mm Ms58 rod rod solid material hexagonal profile

Brass hexagonal 2.0401 SW 5mm-40mm Ms58 rod solid material hexagonal profile

Description:

Brass hexagon with the material number 2.0401 is made of a copper-zinc-lead alloy. The copper content is approx. 57-59 %, zinc - 36-40 % and lead - 2.5-3.5 %. CuZn39Pb3 is the main alloy for machining in Germany. The material is particularly suitable for machining on automatic machines. Brass hexagonal is also easy to stamp, but at the same time has a low corrosion resistance. The material can be hot-formed very well and cold-formed only to a limited extent (because of the danger of stress corrosion cracking). High hardness and strength are achieved through cold formability.

Brass hexagonal has very good machinability and can be easily soft and hard soldered. For welding 2.0401, resistance welding is best recommended. Other welding methods should be avoided. Hexagonal brass can be polished mechanically and galvanised very well.

Hexagonal brass with the designation CuZn39Pb3 Ms58 is widely used in various fields. For example, this material is used to make

- Faucet handles;

- fittings;

- parts for electrical engineering;

- building profiles;

- various shaped turned parts.

Material 2.0401 is characterised by the following features:

- very good machinability;

- good hot forming properties;

- good punching, polishing and galvanising properties;

- low corrosion resistance;

- suitable for automatic machining;

- good soft and hard solderability.

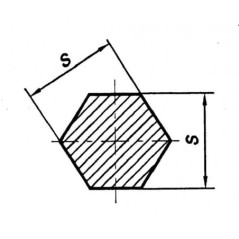

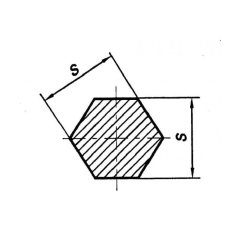

Technical data:

| Brand: | Auremo |

| Manufacturer number: | Not applicable |

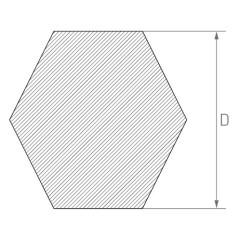

| Type: | Hexagonal |

| Material: | Brass |

| Field of application: | Water tap handles; fittings; parts for electrical engineering; building profiles; various shaped turned parts. |

| Standard classifications: | |

| Material number: | 2.0401 |

| Alloy: | CuZn39Pb3 |

| UNS: | C38500 |

| Further information: | |

| Density: | 8.47 g/cm³ |

| Thermal conductivity: | 123 W/m K |

| Electr. resistance: | 0.066 Ω mm²/m |

| Electr. conductivity: | 15 m/Ω-mm² |

| Tensile strength: | min. 360 MPa |

| Melting point: | 888 °C |

| Surface: | Smooth (may contain handling or storage marks). |