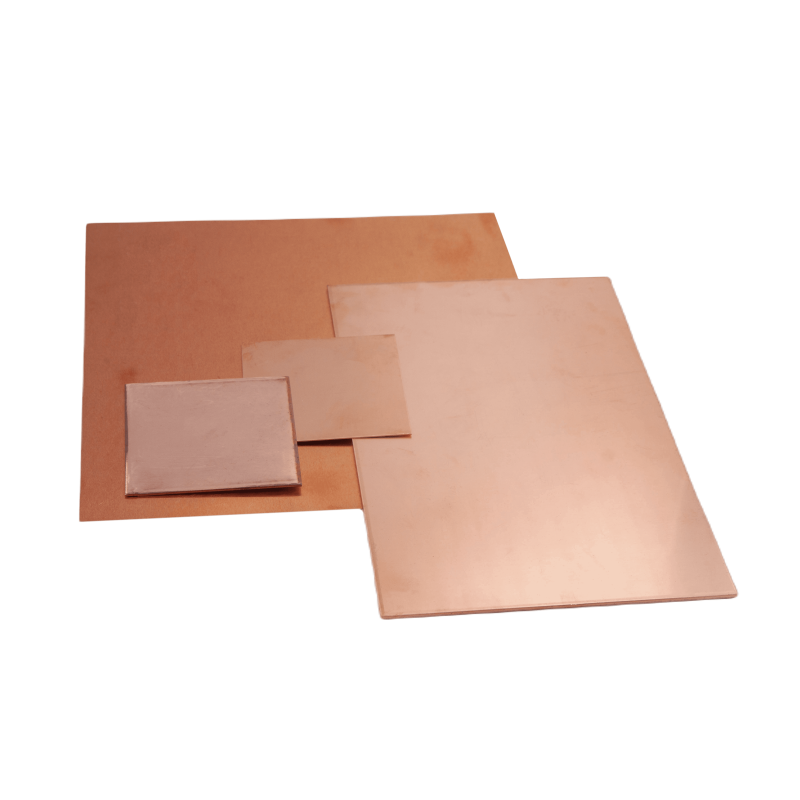

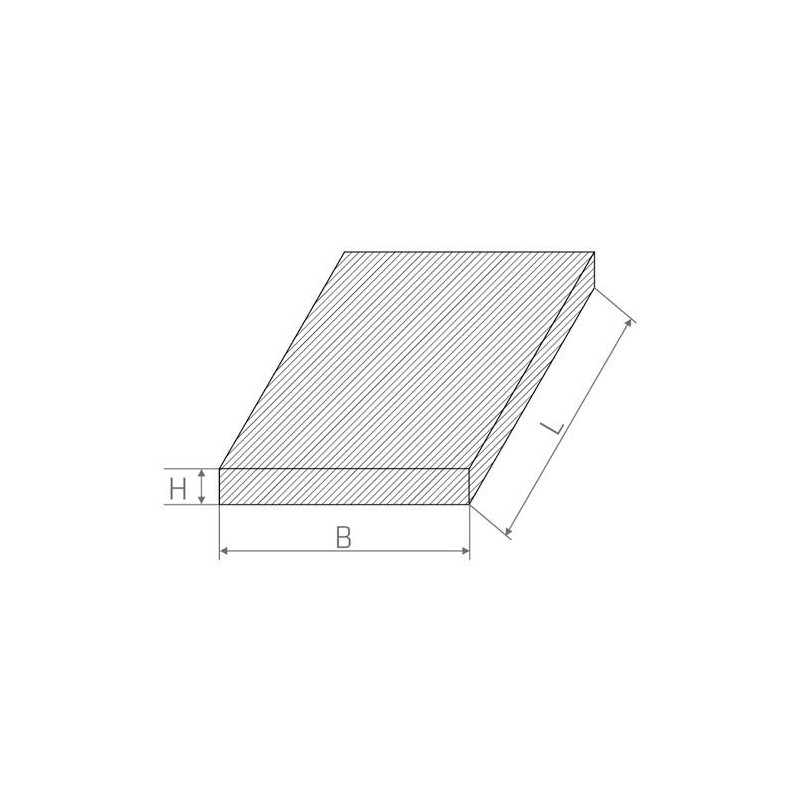

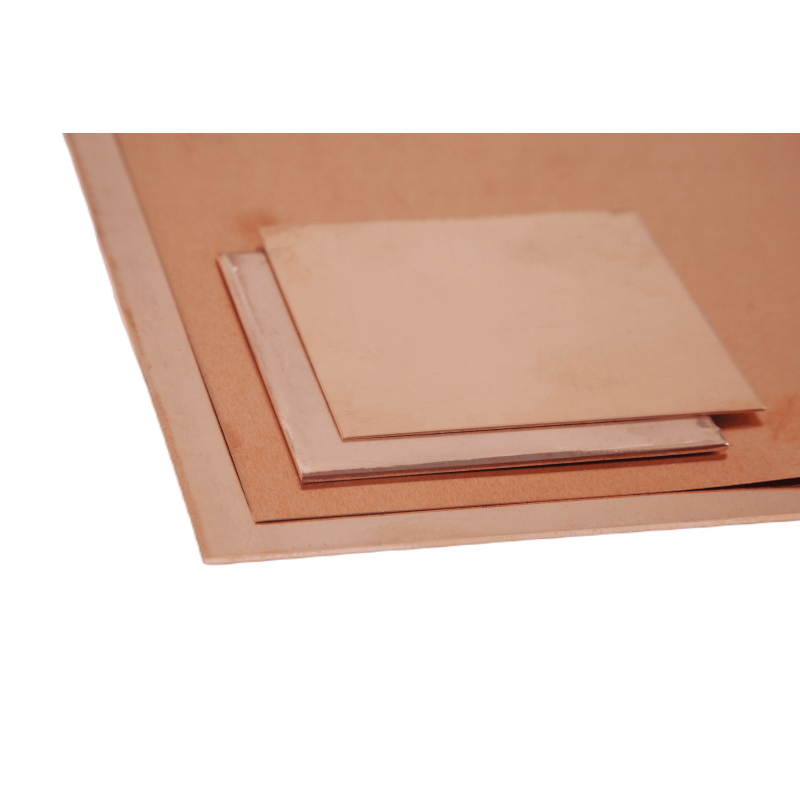

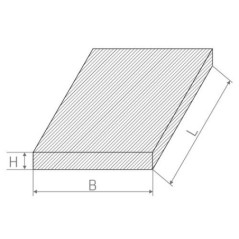

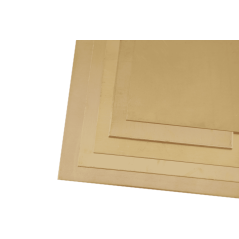

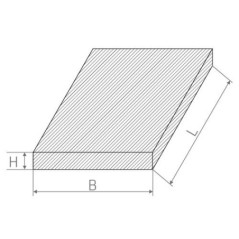

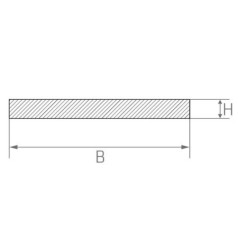

Copper sheet Cu 99% sheets Cut to size Thin sheet selectable Pure copper sheet 0.5-20mm

Copper sheet Cu 99% Sheets Cut to size Thin sheet selectable Pure copper sheet 4-8mm

Description:

Copper can be produced in various forms, but it is most popular in sheet form. After all, there are countless applications that require copper sheet. Regardless of the thickness of the copper sheet, there will always be a use for it. This metal product is so popular that you will have trouble finding out where to buy copper sheets whenever you have a need.

Copper has the highest electrical and thermal conductivity of any major metal. Copper alloys are unique as electrical conductors due to their high conductivity, inherent strength, formability and corrosion resistance, making copper suitable for connectors and other electrical/electronic products. Due to its exceptional corrosion resistance, copper and its alloys are used in a variety of environments and applications. Soldering, brazing, welding, screwing, riveting, crimping and gluing are typical methods for joining copper and copper alloys.

Copper can be used for architectural purposes due to its softness, malleability and excellent formability properties. Copper is strengthened by adding other elements and copper alloys such as brasses and phosphor bronzes and cupronickel.

Properties of copper as a material:

- high conductivity

- good corrosion resistance

- excellent workability

- excellent formability

Main application of sheets made of copper:

- chemical industry

- petroleum industry

- water pipe

- Food industry

- Microelectronics

Chemical composition (in %)

| Cu |

| 99% |

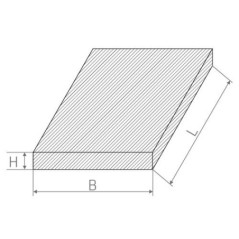

Technical data:

| Brand: | Auremo |

| Manufacturer number: | Not applicable |

| Type: | Sheet, Plate |

| Material: | Copper |

| Mechanical properties (room temperature): | |

| Coefficient of linear expansion 10- 6xK1: | 17.3 |

| Tensile strength Rm: | 240-300 |

| Elongation A5 %: | 8-15 |

| Further information: | |

| Density: | 7.9 g/cm³ |

| Modulus of elasticity kN/mm2: | 130 |

| Thermal conductivity W/(mK): | 394 |

| Electr. resistance: | 0.018 Ω mm²/m. |