Welding wire TIG 2.4627 Welding electrodes NiCr22Co12Mo9 Nickel Welding rods Ø0.8-5mm

Welding wire TIG 2.4627 welding electrodes NiCr22Co12Mo9 nickel welding rods Ø1-5mm

Length tolerance +/-2mm

Description:

Nickel-based alloy with high heat resistance combined with excellent mechanical strength. The material 2.4627 is a high-temperature alloy. These welding rods are used for welding nickel-chromium-cobalt-molybdenum alloys. The material 2.4627 can also be used for overlay cladding where a near alloy is required, e.g. B. in gas turbines and ethylene plants.

The weld metal gives good strength and oxidation resistance above 800 to 1150 °C, especially when welding on base metals of nickel-iron-chromium alloys.

Please note the permissible operating temperatures for the filler material and the base material: 2.4663, 2.4851, 1.4958, 1.4876. Inconel alloys 800HT and 803 and cast alloys such as HK-40, HP and HP-45 Modified.

Properties of the material 2.4610:

- good durability

- resistance to deformation

- excellent corrosion resistance

Use of the material 2.4627:

- high heat resistance

- excellent mechanical strength

- good strength and oxidation resistance

Main application of the material 2.4627:

- gas turbines

- ethylene plants

- Nickel-chromium-cobalt-molybdenum alloys

- Nickel-iron-chromium alloys

If you would like to find out more about the possibilities of our online shop Auremo, we recommend that you take a look at our range. With us you will not only find electrodes, but also wires, sheets, rods and rare metals at reasonable prices.

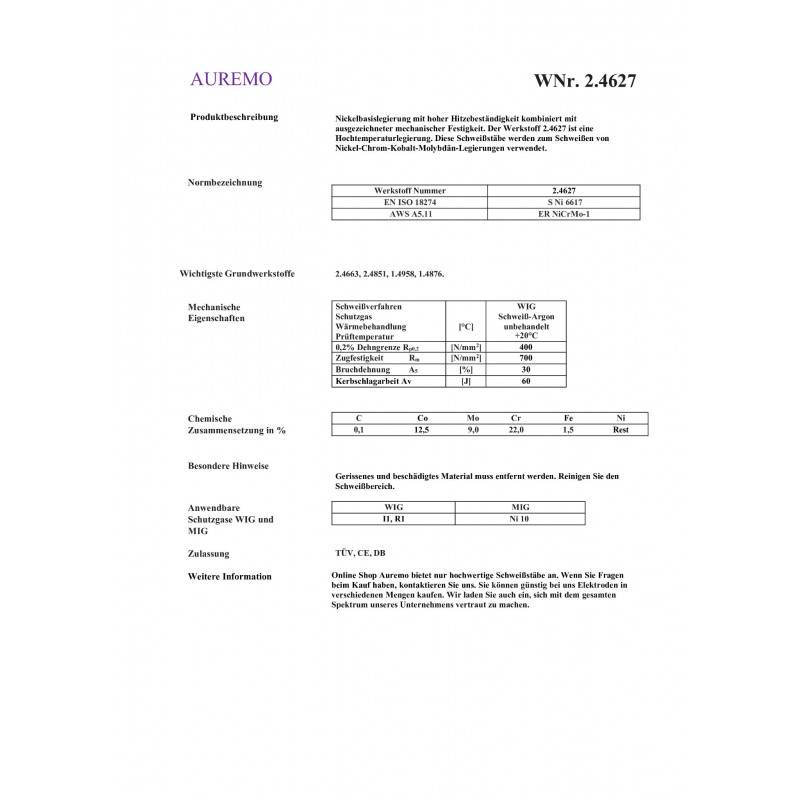

Technical specifications:

| Brand: | auremo |

| Manufacturing Country And Region: | Germany |

| manufacturer number | Not applicable |

| Type: | welding electrodes |

| Norm classifications: | |

| Material number: | 2.4627 |

| EN ISO 18274 | S Ni 6617 |

| AWS SFA-5.11 | ER NiCrMo - 1 |

Chemical composition (in %):

| C | Al | Cr | co | Mon | no |

| 0.1% | 1.2% | 22% | 12.5% | 9% | rest |

Mechanical properties (room temperature):

| Tensile strength Rm MPa | Yield strength Rp 0.2 MPa | Impact work ISO-V J | Elongation at break A5% |

| 700 | 400 | 60 | 30 |