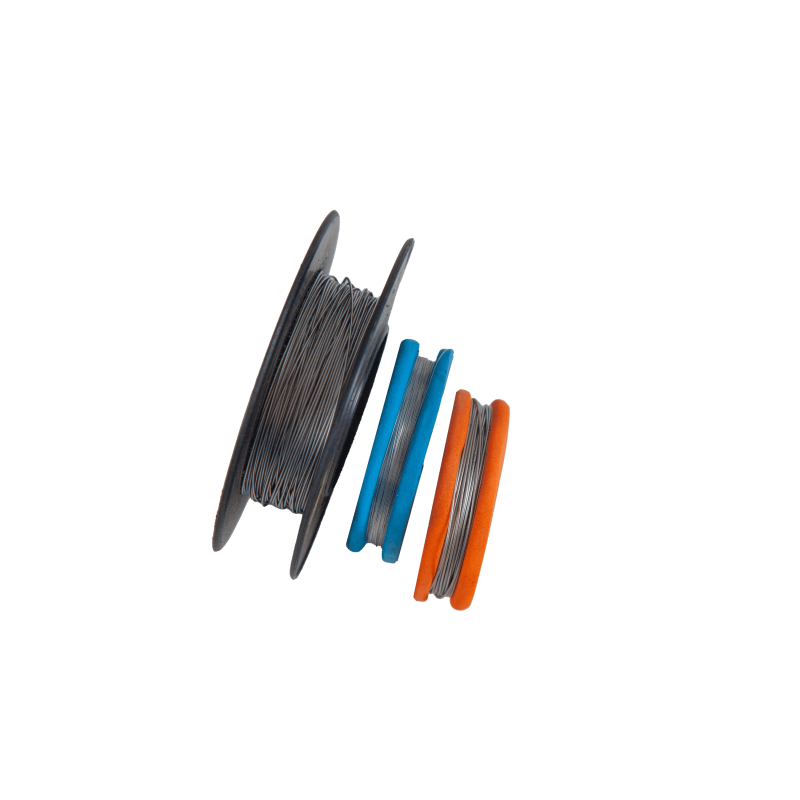

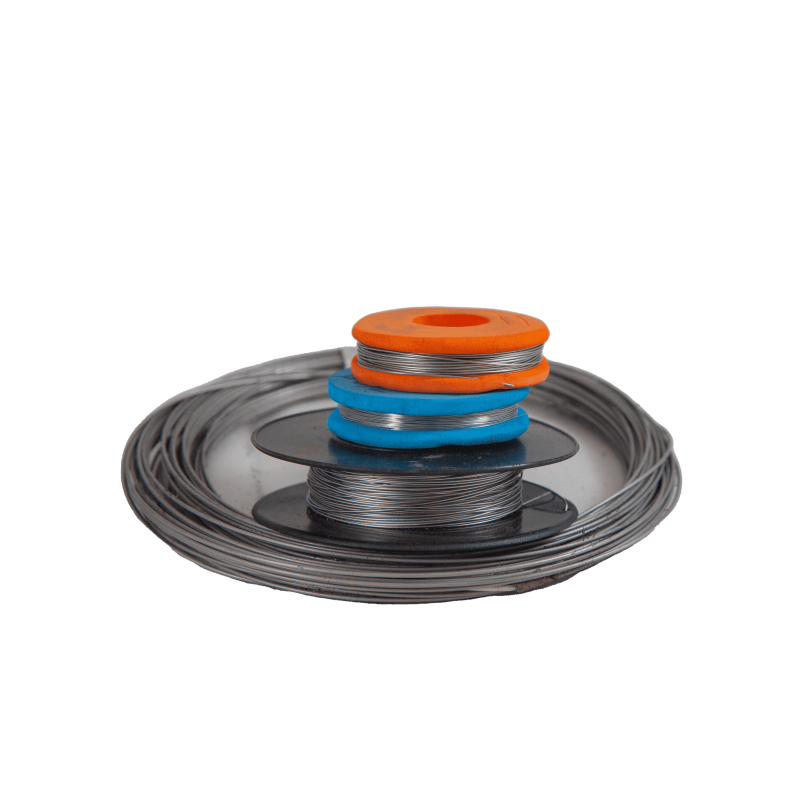

Titanium wire Grade 5 Ø0.5-8mm 3.7165 Ti6Al4V Titanium R56200 1-500 metres

Titanium wire Grade 5 Ø0.5-8mm 3.7165 Ti6Al4V Titanium R56200 1-500 metres

The tolerance for the width and length of a sheet metal blank is +/-2mm

Important: Sheet metal cuts are not suitable for decorative or visible areas. Cutting is done with guillotine shears. Edges sharp! Not all sheets in protective film. Surface pure industrial quality - scratches not excluded! Please enquire separately in advance - we will try to find a solution for you.

Description:

- Production time - none. Already in stock.

- Shipping preparation - 2-3 working days.

- Delivery time - depending on the parcel service. Please look at the faq.

Please note: Cutting with guillotine shears. Cutting tolerance +/- 2mm.

Ti-6AI-4V is the most commonly used alloy of the alpha-beta group and the best known of all titanium alloys. The material has excellent fatigue strength even under humid conditions.

TiAl6V4 (grade 5) has good corrosion resistance in oxidising media, which is due to the formation of a dense, firmly adhering oxide layer. In the event of damage, this layer quickly forms again in the presence of oxygen. Its increasing use as an implant material in medical technology and the jewellery industry is partly due to its excellent biocompatibility.

TiAl6V4 can be hot-formed and cold-formed to a limited extent. Due to its high strength and low modulus of elasticity, strong springback is to be expected during cold forming. For this reason, hot forming is generally preferred.

Properties of the material 3.7165:

- good strength

- good toughness

- good hot formability and weldability

- Very good corrosion resistance

Main areas of application for the material 3.7165:

- Plant and mechanical engineering

- Aerospace industry

- Ultrasonic technology

- Jewellery industry

Online Shop Auremo endeavours to supply you with high-quality rolled products made of non-ferrous metals. All metals are subjected to quality control at various stages of production. Only first-class raw materials are used for the production of titanium rods.

Chemical composition (in %):

| Fe | O | N | Ti | C | V | Al |

| max. 0.4% | 0.2% | 0.05% | Remainder | 0.08% | 3.5-4,5% | 5.5-6.75% |

Mechanical properties (room temperature):

| Hardness HB 30 | 0.2% Yield strength Rp - N/mm2 | Tensile strength Rm | Elongation A5 | Modulus of elasticity kN/mm2 |

| 310 | 830 | 895 | 10% | 114 |

Physical properties (room temperature):

| Density g/cm3 | Specific heat J/kg K | Thermal conductivity W/m K | Electrical resistance Ω-mm2/m |

| 4.43 | 560 | 7.1 | 1.71 |