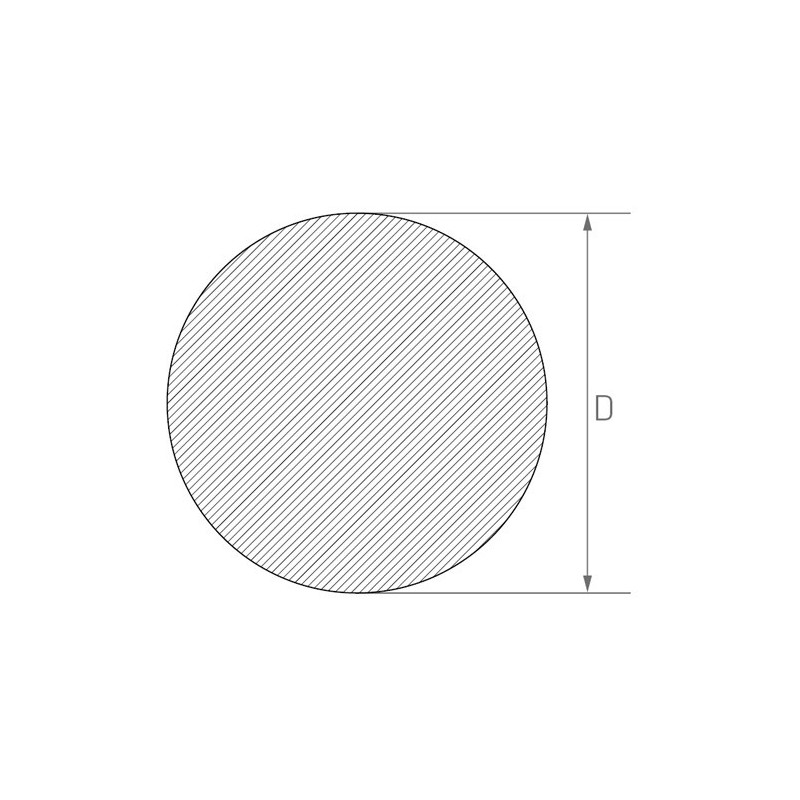

Haynes 25 Round bar 2.4964 from 5.21 to 168.78mm Alloy L605(HS 25) Bar AMS 5759

Properties of material 2.4964: good strength; good oxidation resistance; high corrosion resistance; good weldability;

Main application of material 2.4964: aerospace industry; commercial gas turbine engines; combustion chambers and afterburners; high temperature ball bearings and bearing rings;

Length tolerance +/-2mm

Description:

- Production time - >Production time - 6-7 weeks.

- Shipping preparation - 2-3 working days.

- Delivery time - depending on the parcel service. Please look at the faq.

If you need material 2.4964, buy it in the online shop Auremo at favourable prices.

HAYNES 25 (L605) is a non-magnetic super alloy based on cobalt. Alloy L-605 has good strength up to 2150°F. HAYNES 25 (L605) has good oxidation resistance up to 1900°F. HAYNES 25 (L605) has unique corrosion resistance in very harsh environments. It is highly resistant to hydrochloric acid, nitric acid and wet chlorine (but caution is advised at certain concentrations and temperatures).

The hardness of Alloy L-605 is usually 250 BHN and never exceeds 275 BHN according to specification. Not significantly hardenable. Does not respond to common aging treatments, but strain aging at relatively low temperatures (700-1100°F) may improve creep and fracture resistance if the alloy is used at temperatures below 1300°F. HAYNES 25 (L605) is an austenitic alloy.

Alloy L605 is the strongest of the formable cobalt alloys and is suitable for continuous service up to 1800°F. Due to its long and widespread use, this alloy has been the subject of numerous studies to determine its properties under a variety of conditions, making it an exceptionally well characterised material.

The material 2.4964 is well resistant to high temperature oxidation and carburisation. Although the alloy is not primarily intended for use in aqueous corrosion, it is also resistant to corrosion by acids such as hydrochloric acid and nitric acid as well as to moist chlorine solutions.

Properties of the material 2.4964:

- good strength

- good oxidation resistance

- high corrosion resistance

- good weldability

Main application of the material 2.4964:

- Aerospace industry

- commercial gas turbine engines

- Combustion chambers and afterburners

- High temperature ball bearings and bearing rings

In our online shop Auremo you will find Alloy L-605, we also have a large selection of other materials at favourable prices. If you have any questions, please contact us.

Technical data

| Brand: | Auremo |

| Country and region of manufacture: | Germany |

| Manufacturer number: | Not applicable |

| Type: | Rod, rubbing rod |

| Material: | HAYNES 25 (L605) |

Technical data:

Chemical composition (in %):

| Ni | Cr | Co | Fe | W | Mn |

| 9.0-11.0% | 19.0-21.0% | Rest | 3.0% | 14.0-16.0% | 2.0% |

Mechanical properties (room temperature):

| 0.2% Yield strength Rp - N/mm2 | Tensile strength MPa | Elongation at break A5% | Modulus of elasticity kN/mm2 |

| 345 | 830-1130 | 25 | 225 |

Physical properties (room temperature):

| Density in g/cm3 | Specific heat J/kg K | Thermal conductivity W/(mK) | Electrical resistance Ω-mm2/m |

| 9.1 | 420 | 16 | 0.88 |