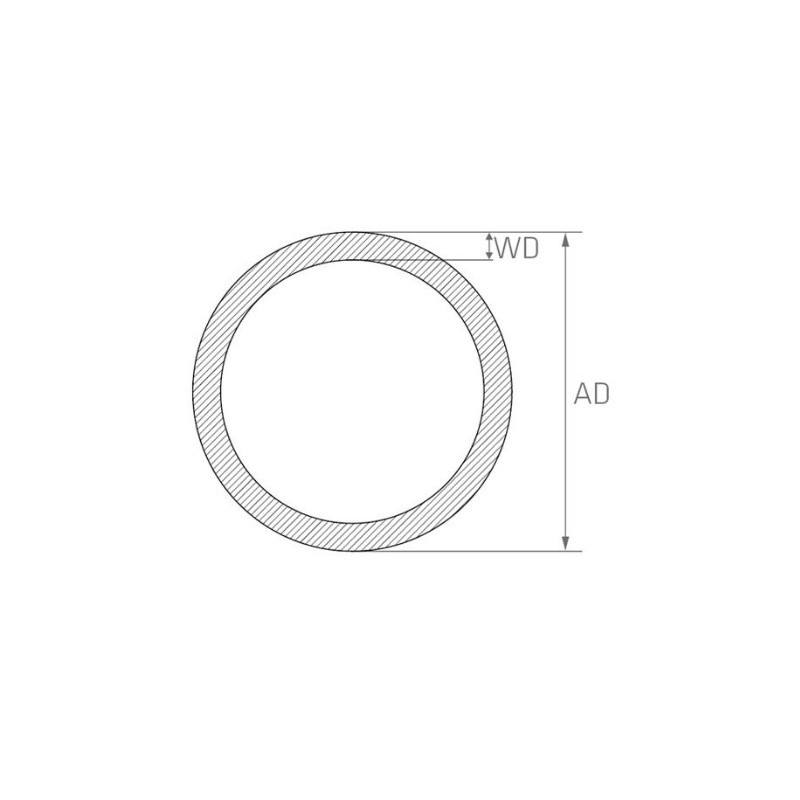

Welded 2.4851 Alloy Inconel® 601 Round tube 2.75x0.5-141.3х6.55mm

Properties of Inconel 601: high oxidation resistance at high temperatures; good resistance to charring; Stability in oxidizing, sulphurous atmospheres; resistant to stress corrosion cracking;

Main application of Inconel 601: high temperature combustors; Elements of exhaust gas neutralization systems; fasteners in heat treatment or heating installations; Containers, baskets, holders in a wide variety of heat treatment systems, e.g. B. for carburizing or carbonitriding; heat-resistant anchors, glow chains and radiant tubes;

Length tolerance +/-3mm

Description:

- Production time - 5-7 weeks.

- Preparation for shipment - 2-3 working days.

- Delivery time - depending on the parcel service. Look at the FAQ please.

If you need welded pipes made of the material 2.4851, you can buy them at the online shop Auremo at reasonable prices.

Inconel® Alloy 601 UNS N06601 is a heat resistant, corrosion resistant nickel-chromium alloy for a wide range of engineering and engineering applications.

Its main properties, which determine its intended use, is long-term resistance to oxidation at high temperatures. In addition, Alloy 601 is easy to machine, resistant to loads and mechanical damage. Thermally deformed cemented carbide is given strength and a stable structure.

Inconel® 601 tubes are used as elements in special kilns for ceramic production and tubes and rolled products are used as heating elements for kilns.

Alloy 601 is used to make a variety of specialty equipment that withstands high service temperatures and is used in the heat treatment of materials (carburizing and carbonitriding).

Inconel® 601 is suitable for the production of individual elements for thermal reactors, gasoline engines, high-temperature combustion chambers and tube support assemblies in the energy industry.

Properties of Inconel® 601:

- high resistance to oxidation at high temperatures

- good resistance to charring

- Stability in oxidizing, sulphurous atmospheres

- resistant to stress corrosion cracking

Main application of the material 2.4816:

- High temperature combustion chambers

- Elements of exhaust gas neutralization systems

- Fasteners in heat treatment or heating systems

- Containers, baskets, holders in a wide variety of heat treatment systems, e.g. B. for carburizing or carbonitriding heat-resistant anchors, glow chains and radiant tubes

Online shop Auremo offers only high quality metals at reasonable prices. If you have any questions, our customer service will be happy to help you.

Technical specifications:

| Brand: | auremo |

| Manufacturing Country And Region: | Germany |

| Manufacturer number: | Not applicable |

| Type: | tube, round tube |

| Norm classifications: | |

| Material number.: | 2.4851 |

| Alloy: | 601 |

| US: | N06601 |

| EN: | NiCr23Fe15 |

Chemical composition (in %):

| no | Cr | Cu | Al | Mn | C | si | S | feet |

| max 58-63% | 21.0-25.0% | 1.0% | 1.0-1.7% | 1.0% | 0.1% | 0.5% | 0.015% | rest |

Mechanical properties (reference values at 20°C):

| 0.2% yield strength Rp - N/mm2 | Tensile strength Rm N / mm² | elongation A5% | Hardness HB 30 | Scale resistance °C |

| 550-750 | 205 | 30 | 220 | 1200 |

Physical properties (approximate values at 20°C):

| Density g/cm3 | Specific heat J/kg K | Thermal conductivity W/(mK) | Electrical resistance Ω mm2/m |

| 8.1 | 450 | 11.3 | 1.19 |