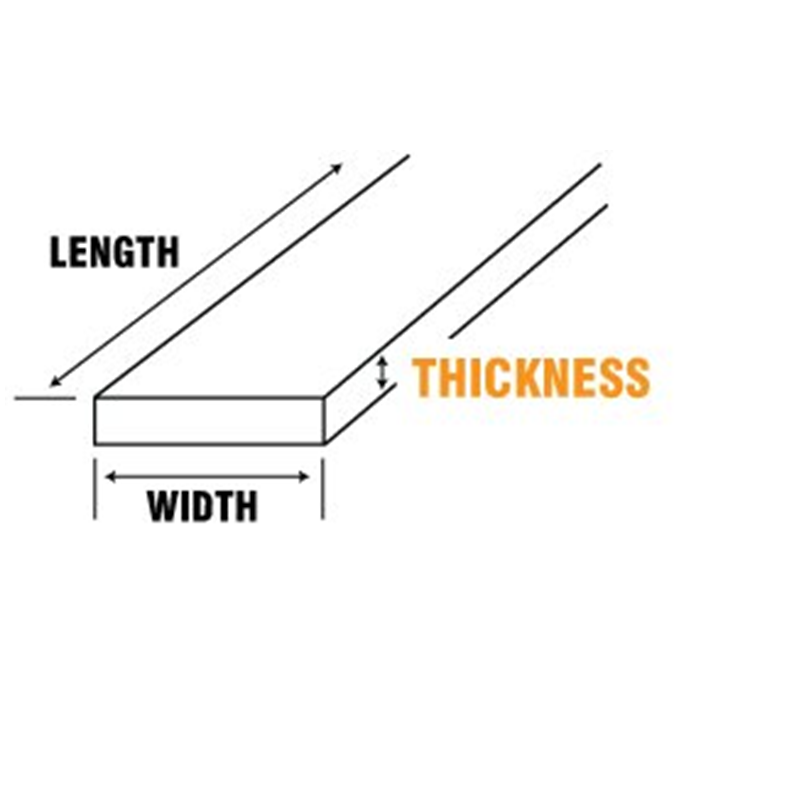

Alloy 617 Inconel sheet from 0.4064mm to 50.8mm plate 2.4663 Cut to size 100-1000m

Properties of material 2.4663: good strength up to 1100 ° C; high temperature resistance up to 1100 ° C;

Main application of the material 2.4663: components in gas turbines; petrochemical industry;

Length tolerance +/-3mm

Description:

- Production time - 5-7 weeks.

- Shipping preparation - 2-3 working days.

- Delivery time - depending on the parcel service. Look at the faq please.

Material 2.4663 is a solid solution reinforced nickel-chromium-cobalt-molybdenum alloy. It has exceptional high temperature strength and good oxidation resistance. Material 2.4663 has excellent resistance to a wide range of corrosive environments. Sheets of 2.4663 material can be formed and welded with ease using standardised techniques.

The high nickel and chromium contents make the alloy resistant to a variety of both reducing and oxidising media. The aluminium, in combination with the chromium, provides oxidation resistance at high temperatures. Solid solution strengthening is imparted by cobalt and molybdenum.

The combination of good strength and oxidation resistance at temperatures above 1000 °C makes 2.4663 an attractive material for such components as ducts, combustion tubes and transition linings in both aircraft and land-based gas turbines. Because of its resistance to high-temperature corrosion, the alloy is used for catalyst grid supports in the production of nitric acid, for heat treatment baskets and for reduction boats in molybdenum refining. Alloy 617 also offers good properties for power plant components.

Properties of the material 2.4663:

- good strength up to 1100 ° C

- high temperature resistance up to 1100 ° C

Main application of the material 2.4663:

- components in gas turbines

- petrochemical industry

In our online shop Auremо you can find various sizes of nickel sheets, also we have a wide range of other sheets at a favourable price. If you have any questions, please contact us.

Technical data:

| Brand: | Auremo |

| Country and region of manufacture: | Germany |

| Manufacturer number: | Not applicable |

| Material: | Nickel |

| Type: | Plate, Sheet |

| Standard classifications: | |

| Material number: | 2.4663 |

| Alloy: | 617 |

| UNS: | N06617 |

| EN: | NiCr23Co12Mo |

Chemical composition (in %):

| C | Fe | Co | Cr | Mo | Ni | Ti | Cu | Al |

| max. 0.05-0.1 % | 2.0% | 11.0-14.0% | 20.0-23.0% | 8.5-10.0% | Rest | 0.2-0.6% | 0.5% | 0.7-1.4% |

Mechanical properties (room temperature):

| 0.2% Yield strength Rp - N/mm2 | Tensile strength Rm | Elongation at break A5 % | Modulus of elasticity kN / mm² |

| 300 | 690 | 35 | 212 |

Physical properties (guide values at 20°C):

| Density g/cm3 | Specific heat J/kg K | Thermal conductivity W/(mK) | Electr. resistance Ω-mm2/m |

| 8.4 | 420 | 13.4 | 1.22 |